SolidCAM is the manufacturing suite for easiest, fastest, most efficient CNC (computer numerical control) simulation and programming facility that can be done directly inside SolidWorks. SolidCAM is a popular add-in of SolidWorks. Moreover by using SolidCAM the steps of operation, parameter details can be set in a way to save time, cost, tool lives etc. SolidCAM helps understand the concept, operation and importance of using CAM software in modern day manufacturing industries. Finally the G-codes are automatically generated for the practical use in CNC machine. After the steps are defined the whole process is simulated in various modes.

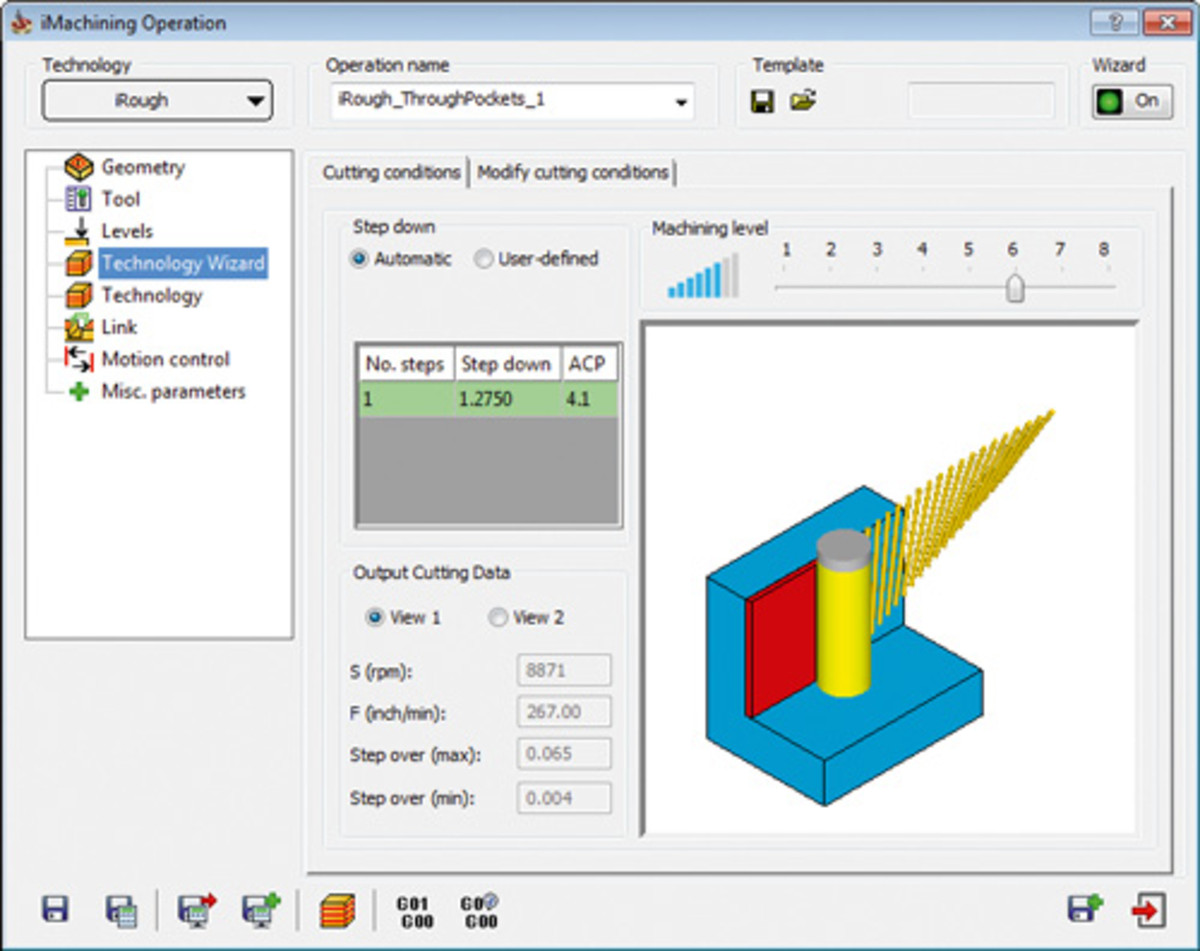

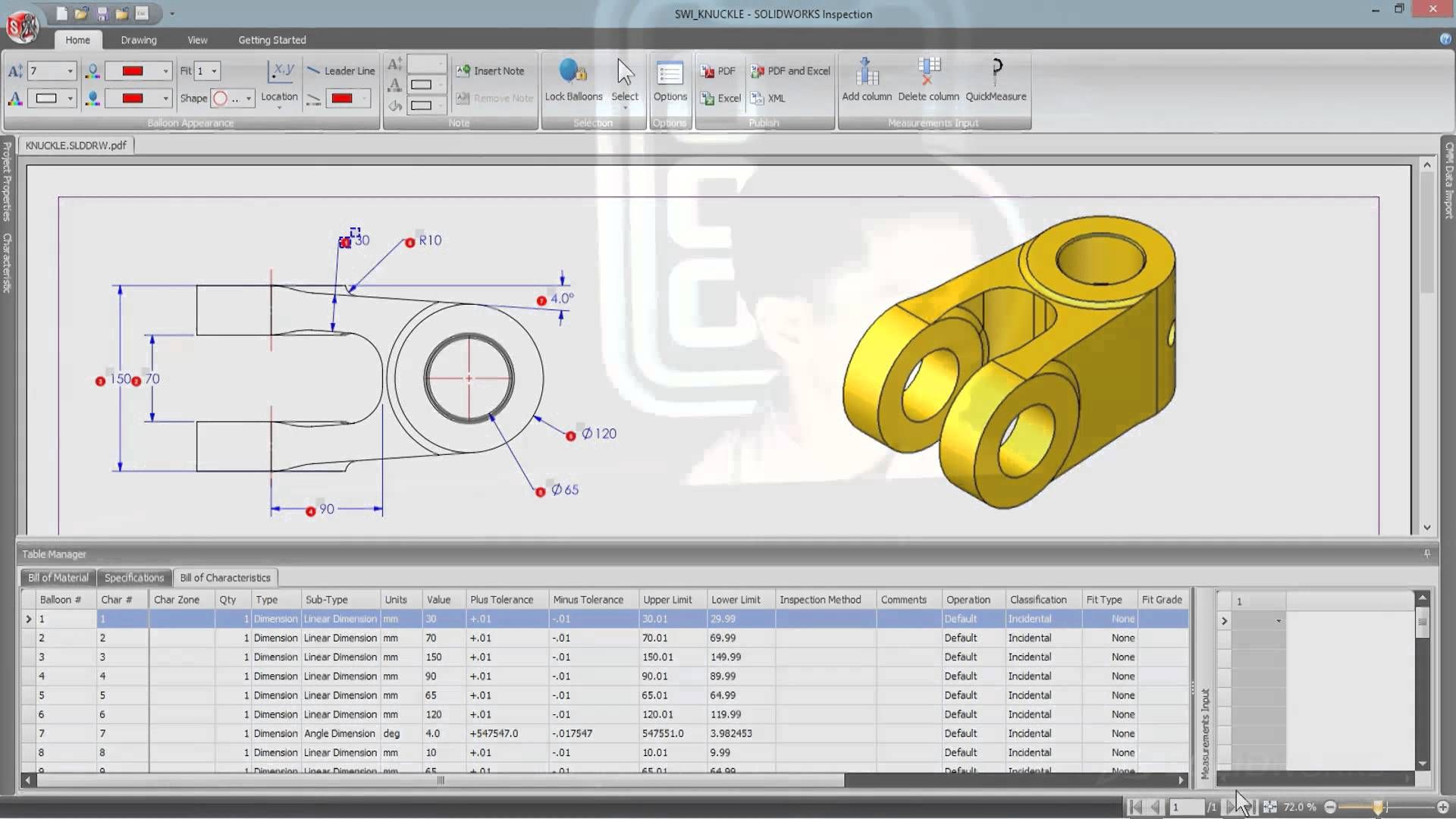

In this paper, SolidCAM iMachining is studied and the detailed procedures of the machining process of a spur gear from stock material is descry-bed step by step by using SolidCAM 2014 2D iMachining technology. The simulation process makes it possible to observe the operations in real time conditions and makes the g-code flaw-(Sultana, N.) less for physical operation. A great variety of machining operations on different stock objects for producing various products can be easily defined *Corresponding author: by using this suite which results in increased flexibility. The iMachining Simulation technology uses a intelligent, patented algorithms for specific operations to optimize G-code the tool path, reduce machining time, tool wear etc.

SolidCAM CNC iMachining is a real breakthrough in CNC milling tool path technology. It provides a seamless si-SolidCAM iMachining ngle window integration and full associativity with the SolidWorks model. SolidCAM is the manufacturing suite for Keywords: easiest, fastest, most efficient computer numerical control (CNC) simulation and prog-CAM amming facility that can be done directly inside SolidWorks. ARTICLE INFO SolidCAM is a popular add-in of SolidWorks.

0 kommentar(er)

0 kommentar(er)